HylyPure

Cost-efficient transportation of green hydrogen made possible by custom processes based on membrane gas permeation and adsorption

The storage of electrical surplus energy from alternative sources (wind, solar power, etc.) is a key challenge of our energy transition. The Power-to-Gas concept offers a promising approach. Electrical surplus energy is used to produce a storable energy carrier like hydrogen or methane. Hydrogen is well qualified due to the CO2 neutrality and the highly efficient end-use applications. As the production of energy often takes place far away from the end users an energy-efficient transport of the energy carrier is highly essential.

The idea

The storage of fluctuating electrical excess energy from renewable sources (e.g. wind, solar power) is a key challenge of our energy transition and has gained significant importance during the last few years. With various Power-to-Gas concepts excess electric energy can be used to produce storable green hydrogen with alkaline or PEM electrolysis. The idea of the proposed concept is to feed this green hydrogen into the existing, well developed natural gas grid, transport it cost-efficiently and separate it with fuel cell quality at arbitrary locations.

Regulatory framework

Statutory regulations limit the hydrogen content in the Austrian gas grid to a certain maximum value of 4 % v/v. The concept allows to extract hydrogen from mixtures with natural gas and provides this hydrogen in fuel cell quality (purity of 99,97 % according to ISO 14687-2:2012) for further utilization.

Implementation

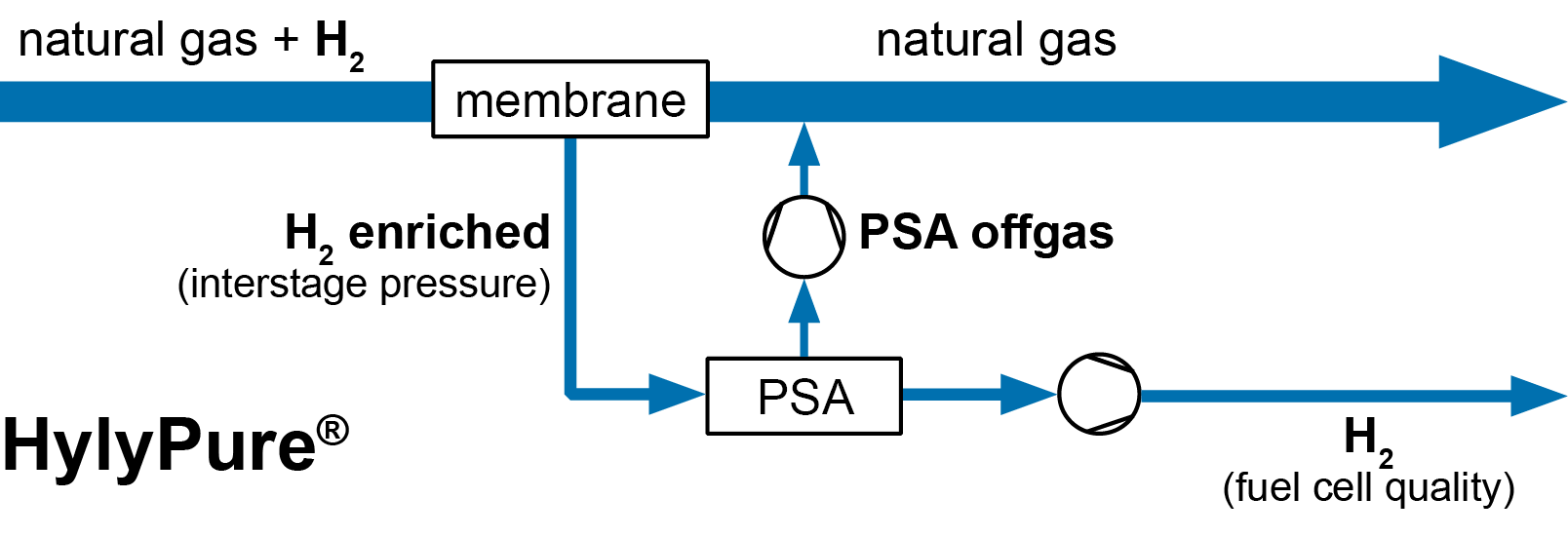

The developed concept incorporates a first pre-concentration step applying membrane-based gas permeation for an energy-efficient enrichment to approx. 40 % v/v hydrogen and a drastic mass flow reduction. Subsequently, hydrogen is purified to the desired qality using pressure swing adsorption (PSA) as a second process step. Finally, the gas quality is thoroughly analyzed to verify the compliance for the desired application (i.e. fuel cell in the current work).Both process steps, gas permeation and PSA, provide enough degrees of freedom to allow for a proper and efficient control of the product gas quality.

Figure 1: HylyPure concept

Optimization

Based on the extensive practical know how of the research group in the field of gas separation a newly developed numerical model will be used for the optimization process in addition to experimental data regarding membranes and absorption. The numeric method will combine an experimentally validated finite difference solver for the simulation of the membrane gas permeation and an experimentally validated dynamic adsorption model in combination with a numeric Levenberg-Marquardt procedure for the process optimization. These effective combinations allow to develop and scale custom designed multi-stage plants. The simulation assisted design enables the identification of an optimal interconnection and scaling of the process steps. Besides the optimization of the single steps, the whole concept is designed for highest energy efficiency and economic viability.

Results

The result of the developments of the Vienna University of Technology in cooperation with OMV AG will be a compact plant which is able to separate hydrogen from a natural gas/hydrogen gas mixture with fuel cell quality. The residual mixture of substances will be compressed to the original pressure and refeeded to the gas grid. If the required electrical energy is generated from renewable energy, this is a CO2 neutral method for separation

The benefits for you

The Vienna University of Technology’s know how enables:

- Optimal hydrogen separation with optimal combination of hydrogen yield, required process energy and investment costs

- CO2 neutral separation

- Hydrogen with fuel cell quality

- Solutions for process integration and automation

Partners & financing

This project is sponsored by “Klima- und Energiefonds” and is realized within the scope of the program “ENERGY MISSION AUTRIA”. The OMV Gas & Power actively supports as a project partner.

Go to top