moBi

moBi – Mobilization of membrane based biogas upgrading plants

Duration: 2015 – 2017

© SpiritDesign – Innovation and Brand GmbH

Background

Renewable and sustainable energy production is a key point for achieving the goal of limiting global warming to less than 2 °C. Additionally to known alternative energy sources like solar, water and wind power, also biogas produced from organic waste can be an attractive energy source. Especially, in developing countries biogas produced from organic waste could not only reduce the dependency of farmers on fossil energy sources but also the part of organic waste rotting uncontrolled and thereby emitting methane into the atmosphere, a gas with a GWP (Global Warming Potential) 29 times higher than carbon dioxide.

Biogas mainly contains methane (45 to 70 %) and carbon dioxide, besides trace impurities like ammonia, hydrogen sulphide or siloxanes. The usage of raw biogas for combustion in gas engines and generation of electric power yields in an efficiency of only 35 to 40 % due to the high amount of incombustible CO2 and the limited electric efficiency of small to medium scale gas engines. Moreover, impurities like CO2 and H2S in the biogas may cause corrosion, other impurities like siloxanes and dust may cause mechanical wear. H2S is not only highly corrosive but also the most toxic gas occurring in biogas as already very low concentrations can be lethal. In order to use biogas as fuel these impurities have to be removed.

Goal of the project

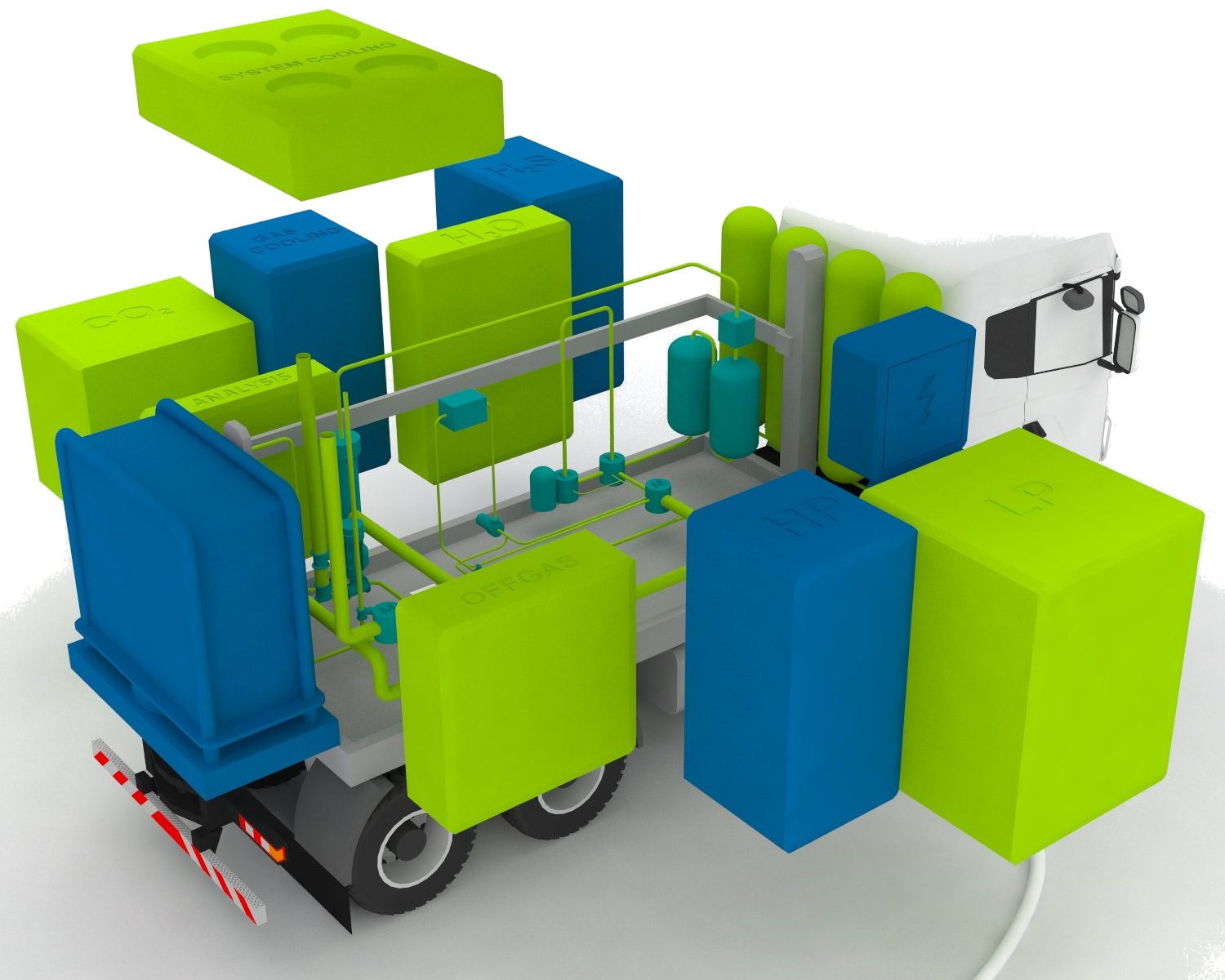

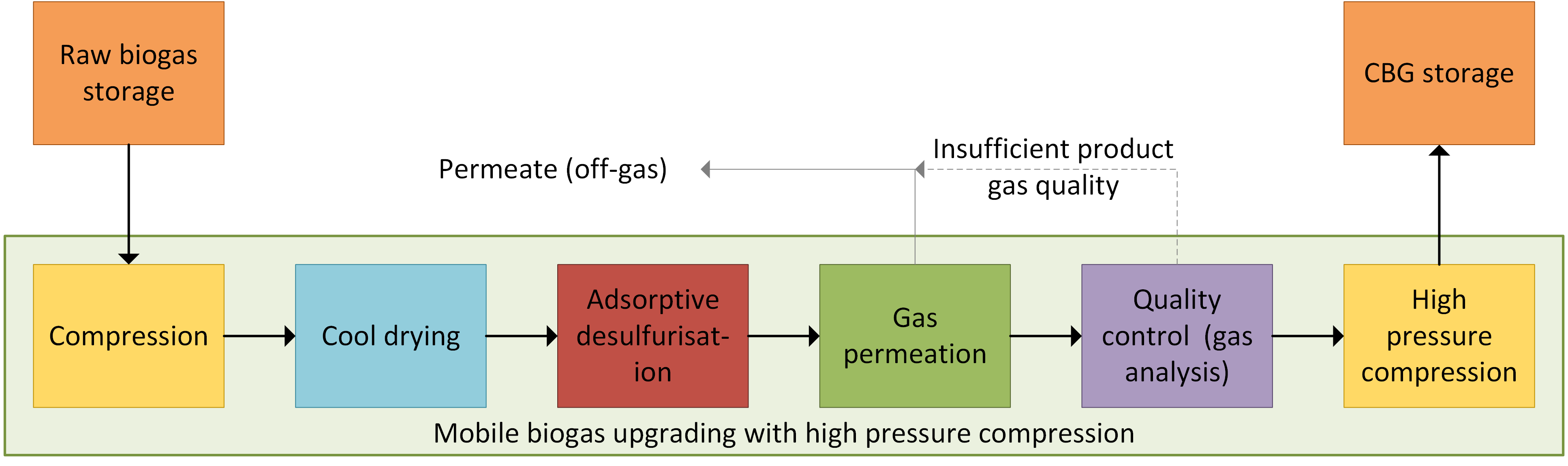

Small farmers cannot afford these biogas upgrading plants due to high investment costs. Thus, a mobile biogas upgrading plant travelling from one biogas plant to another for removing these impurities is developed. Such plants dramatically reduce investment costs for single farmers and thus, make it affordable for them. For storing and transportation issues the product gas will be compressed after the upgrading process. Paraná in southern Brazil was chosen as test environment. Like in many other regions in the world, especially in Central America, South East Asia and the tropics, a big amount of seasonal waste coming from cassava processing is available in Paraná. Still, the biggest amount of potential waste for biogas plants are typical agricultural wastes like manure from swine, cattle and chicken.

Methods

In order to choose an appropriate design of the biogas upgrading plant investigation on real biogas data from Brazilian farmers was carried out. The most important points are the large range of CH4 concentration in the biogas occurring not only between different biogas production plants but also at one single place at different times and the high concentration of H2S.

Due to raw biogas compositions and further requirements, like low space and weight demand, short start up time, low energy demand and low costs, membrane process was chosen for the removal of CO2, which is the main upgrading step. Additionally, two further pre-treatment steps were defined: cool-drying for the removal of water vapor and potential ammonia and an adsorption step with two different adsorbents for desulphurization and removal of minor impurities like O2 and siloxanes. Due to extremely high H2S concentrations in raw biogas originating from manure, biogas plants using manure as substrate need an additional stationary pre-desulphurization before the biogas can be upgraded in the mobile plant.

The whole process was investigated by a process simulation in Aspen Plus®, which focused on the membrane separation step. It was shown that a process with a two-stage membrane step can meet the Brazilian biomethane limit of 96.5 % methane in the product stream. Designs with membrane area adjustable to the incoming feed composition were able to reduce the CH4 loss into the off gas significantly at high CH4 concentrations in the feed, while product quality remained above the biomethane limit. Currently, generation of energy and mass balances and investigation on possible savings potential are carried out.

Outlook

Subsequent to the development of this virtual prototype, which will be finalized this year, development and experimental investigation on a real prototype is planned.

Partners & Funding

- SpiritDesign – Innovation and Brand GmbH

- TU Wien – Institute of Chemical, Environmental & Biological Engineering

- CIBiogás NPO

Founded by Vienna Business Agency. A service offered by the City of Vienna

Go to top