SHOCOTEC

Intensified chemical oxidative scrubbing for biogas desulfurization

General information

The chemical oxidative scrubbing process was refined by the research staff of the Institute Chemical, Environmental and Bioscience Engineering at TU Wien during a research project funded by FFG(Austrian research Promotion Agency). The aim was to increase the process safety while decreasing the necessary space as well as the consumption of chemicals.

The SHOCOTEC technology offers a competitive biogas desulfurization process to the market that is characterized by its easy implementation into existing plants, the possibility of complete automation and low maintenance requirements.

Figure 1: Basic flow sheet of the intensified chemical oxidative scrubbing for biogas desulfurization

Process overview

The basic principle of contacting the biogas with alkali hydroxide solution, e.g. sodium hydroxide, is the same as for commonly used chemical oxidative scrubbing processes. Instead of a basic column a special short time contactor is used. This offers multiple advantages compared to other commercial systems. It intensifies the contact between the biogas and the liquid scrubbing solution, while reducing the needed space. Due to the very short and well-adjusted contact time it is possible to achieve an excellent selectivity for the absorption of hydrogen sulphide compared to carbon dioxide. The reduced carbon dioxide absorption leads to a decreased consumption of the used chemicals. In the next step the two phase system of biogas and scrubbing liquids is separated and the biogas leaves the treatment plant mostly free of scrubbing liquids. The loaded scrubbing chemicals are then fed to an oxidative treatment step (e.g. using hydrogen peroxide) and the absorbed sulphur is converted to non-dangerous aqueous sodium sulphate solution.

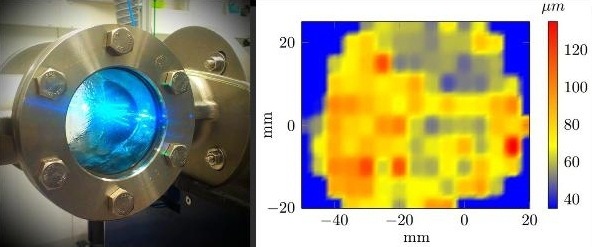

Figure 2: Left: Examination of the biogas scrubbing liquid mixture using a laser based flow measuring technique; Right: Example for the droplet size distribution in the contactor

(Source: TU Wien)

The determining step to achieve an efficient and selective absorption of sulphur hydrogen from biogas is the exact control of the contact time between scrubbing liquids and the gas phase as well as the homogeneous distribution of the liquid in the gas phase. To achieve this, different types of contactors and spray nozzles were tested using a laser based flow measurement technique (phase Doppler anemometry).

Figure 3: Mobile SHOCOTEC prototype for a volume flow rate of 200 Nm³/h

Figure 4: Multi stage pilot plant based on the SHOCOTEC concept for volume flow rates of 500 Nm³/h

The main advantages of the new process compared to state of the art techniques are:

- very compact design and therefore cost effective scale up

- high process security

- straightforward operation

- easy integration in biogas plants

- high pressure stability

- low investment and running costs

- high degree of automation

- low consumption of simple and common chemicals

Figure 5: Size comparison of the SHOCOTEC prototype with conventional chemical and biological biogas desulfurization for similar volume flow rates

Dissemination

The concept and the SHOCOTEC prototype was presented to the public by research staff of the Vienna Universuty of Technology at the Hannover Messe 2014, the largest industry fair worldwide. It was showcased at the TU Wien shared booth which generated a large interest from the visitors.

Figure 6: Presentation of the SHOCOTEC prototype and the process concept at the TU Wien shared booth at the Hannover Messe 2014, visit of the European Commissioner for Energy Günther Oettinger

The leaflet for the Hannover Messe 2014 can be downloaded here.

Furthermore the project was presented at the Biogas 2.0 event. The German presentation and programme booklet can be downloaded at the webpage of the Klima- und Energiefonds.