EE-Methan

EE-Methan aus CO2 - Development of a catalytic process for the methanation of CO2 from industrial sources

Starting position

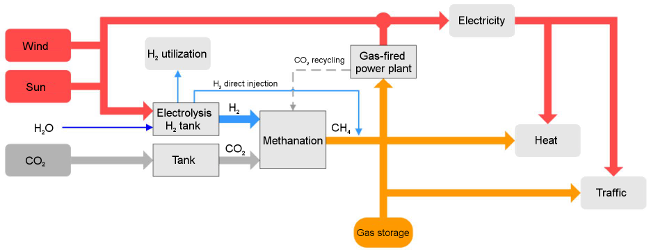

The fact that the percentage of renewable energy production is still increasing, leads to a higher fluctuation in the international energy production. Taking into account that the energy consumption is also variable leads to a high volatility concerning capacity and price of electric current. Already seasonal fluctuations in energy production are reaching the capacity limits of nowadays power grids. Stable prices and optimal usage of the existing grid capacity are only achievable by generating a constant utilisation of power grids. An example of how to achieve this goal is temporary storage of electrical power. Today’s solutions are limited by number of different factors – limited capacity (batteries, capacitor), missing practicability (fly wheel, compressed-air storage), a reduced number of possible operation sites (pump storage) and also high costs. In this context Power-to-Gas (P2G) offers a huge potential. Hydrogen produced by electrolysis using excess energy is combined with carbon (mostly CO2 produced by power plants, industrial or biogenic processes) and chemically or biologically transformed to methane. After appropriate gas purification this gas can be fed to the natural gas grid. In addition to methane there is also the potential option to directly feed hydrogen to the natural gas grid, which is currently examined. Assuming renewable energy resources sum up to 80% of the total electricity generation current estimations come to the conclusion that the natural power grid offers 8-times the capacity that is needed to compensate for the seasonal fluctuations and is therefore a very potent energy storage option. Furthermore the overall efficiency of the concept electricity-gas-electricity is specified around 40-50%. Extending this concept with liquid energy carriers (e.g. ethanol or butanol) leads to additional synergetic effects. The result is a complex overall concept with many degrees of freedom, leading to lots of options in regards to customization and optimization adapted to the local needs.

Aims and goals

The aim of the RSA project “EE-Methane aus CO2” is to develop a catalytic process that is adjusted to the boundary conditions of the renewable energy methane production. The main innovation is a honeycomb-type catalyst which is used in combination with a staged reactor system. The results can be used for the dimensioning and development of methanation plants for the utilization of CO2 from industrial point sources and chemical storing of electrical power in the form of synthetic methane which can be fed into the natural gas grid.

Process overview of the EE-Methan project

Approach

The most important design steps are the following:

- Development of a honeycomb methanation catalyst using a ceramic carrier material. It should be adapted to the CO2 sources and therefore offer an improved lifetime of at least 10% higher than compared to commercially available methanation catalysts.

- Development of a matching stage reactor system that is ased on a better temperature control (heat extraction between the combs). The controlled recycling of product gas leads to a better yield and conversion rate than existing reactors. Determination of the optimal process parameters for different CO2 sources (e.g. power plant off-gas, biogas).

- Development of fitting strategies for the use of extracted heat e.g. from nearby industrial companies (power plants or biogas plants) that also serve as CO2 suppliers

- Conditioning of the product gas up to a quality that can be fed to the natural gas grid

- Overall ecologic and economic assessment of the process including an overall CO2 balance based on accompanying studies.

Scientific project partners

- Energy Institute at the Johannes Kepler University Linz

- PROFACTOR GmbH, Department for Innovative Energy Systems

- Montanuniversität Leoben – Institut für Verfahrenstechnik des industriellen Umweltschutzes

- Vienna University of Technology – Institute of Chemical Engineering

Go to top