OptFuel

OptFuel – Optimization of energy carrier production from biomass by using excess energy

Starting position

The fact that the percentage of renewable energy production is still increasing, leads to a higher fluctuation in the international energy production. Taking into account that the energy consumption is also variable leads to a high volatility concerning capacity and price of electric current. Already seasonal fluctuations in energy production are reaching the capacity limits of nowadays power grids. Stable prices and optimal usage of the existing grid capacity are only achievable by generating a constant utilisation of power grids. An example of how to achieve this goal is temporary storage of electrical power. Today’s solutions are limited by number of different factors – limited capacity (batteries, capacitor), missing practicability (fly wheel, compressed-air storage), a reduced number of possible operation sites (pump storage) and also high costs. In this context Power-to-Gas (P2G) offers a huge potential. Hydrogen produced by electrolysis using excess energy is combined with carbon (mostly CO2 produced by power plants, industrial or biogenic processes) and chemically or biologically transformed to methane. After appropriate gas purification this gas can be fed to the natural gas grid. In addition to methane there is also the potential option to directly feed hydrogen to the natural gas grid, which is currently examined. Assuming renewable energy resources sum up to 80% of the total electricity generation current estimations come to the conclusion that the natural power grid offers 8-times the capacity that is needed to compensate for the seasonal fluctuations and is therefore a very potent energy storage option. Furthermore the overall efficiency of the concept electricity-gas-electricity is specified around 40-50%. Extending this concept with liquid energy carriers (e.g. ethanol or butanol) leads to additional synergetic effects. The result is a complex overall concept with many degrees of freedom, leading to lots of options in regards to customization and optimization adapted to the local needs.

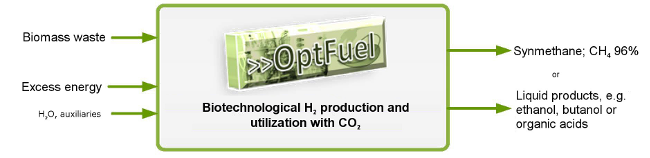

Figure 1: Process overview of the OptFuel project

Aims and goals

The higher-ranking goal of the RSA-project “OptFuel” is the development of an optimized overall process for the generation of methane and liquid products (alcohols and organic acids) from biogenic waste by the use of excess current from fluctuating, renewable energy sources.

The aim is the conversion of carbon dioxide in utilizable energy carriers like methane, ethanol or butanol to achieve a maximized resource efficiency. At the end of the project a continuous pilot-plant will be realized in a technical centre displaying the optimized overall process. This plant then represents the basis for a first industrial-scale demonstration plant.

Approach

The most important design steps are the following:

- Overview of the research and development status of the individual process steps and the amount of accessible biomass waste in Austria

- Determination of the frame conditions for the combined single processes of the project in regards to process engineering

- Influence of substrate and substrate pre-treatment on H2-fermentation: the chosen pre-treatment of the raw materials guarantees an efficient usage under optimal process parameters (temperature, pressure, dry matter contents) in the H2-Fermentation. Continuous product removal leads to a maximized yield of Hydrogen.

- Determination of the purification requirements of the H2/CO2 gas mixture for the CO2 utilization modules

- Determination of the efficiency of CO2 stripping for the improvement of the H2 yield

- Investigation of yield and kinetics of biological CO2 utilization and chemical methanation

- Quantification of the energy demand respectively the selectivity of the product purification

- Effectiveness of the storage of excess current through the inclusion of hydrogen electrolysis in biotechnological processes

- Economic and ecologic process evaluation including the determination of specific initial cost for all products of the OptFuel process, as well as sensitivity analysis of substrate prizes, product prizes and electricity rate.

- CO2 balance using a life cycle assessment

- Costing of a demonstration plant

Scientific partners for the project

- Energy Institute at the Johannes Kepler University Linz

- PROFACTOR GmbH, Department for Innovative Energy Systems

- Montanuniversität Leoben – Institut für Verfahrenstechnik des industriellen Umweltschutzes

- Vienna University of Technology – Institute of Chemical Engineering

Go to top